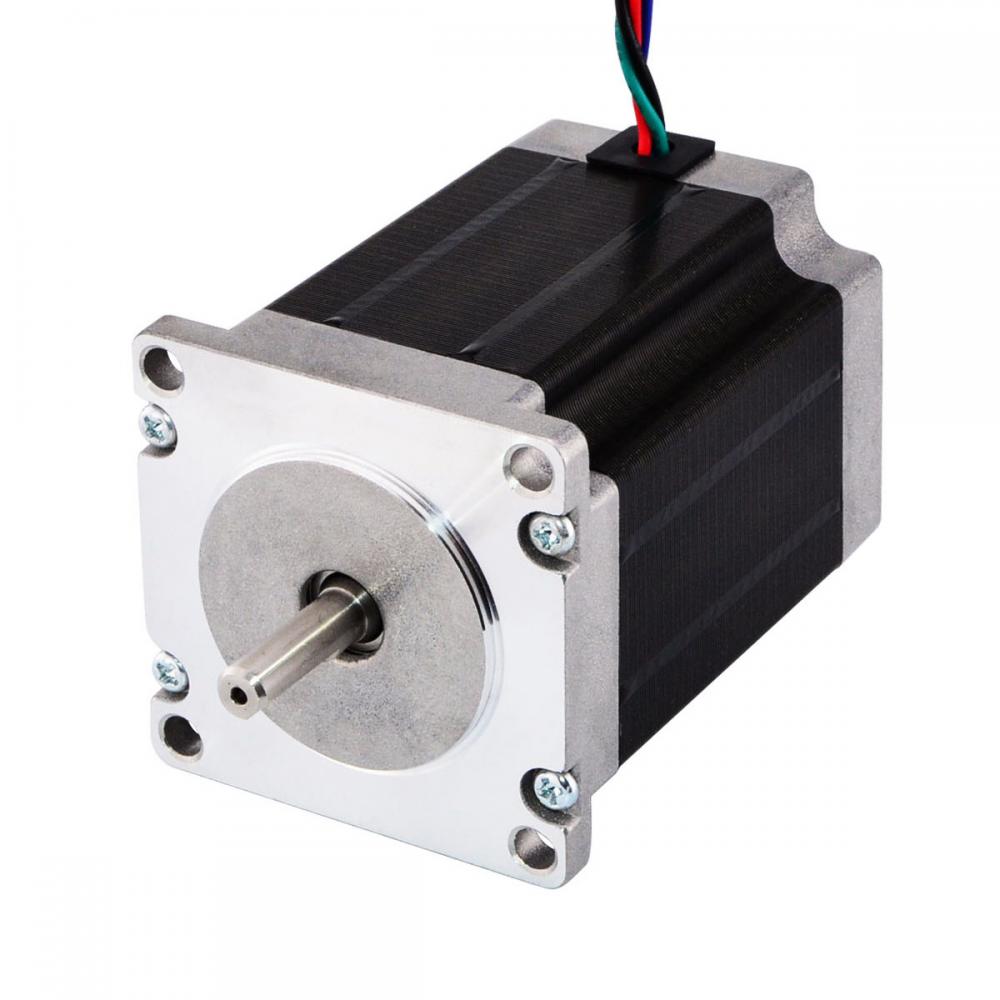

Stepper motors are DC motors that move in discrete steps. They have multiple coils that are organized in groups called “phases”.

By energizing each phase in sequence, the motor will rotate one step at a time. With a computer controlled stepping you can achieve very precise positioning and/or speed control. For this reason, stepper motors are the motor of choice for many precision motion control applications.

Stepper motors come in many different sizes and styles and electrical characteristics.

This guide details what you need to know to pick the right motor for the job.

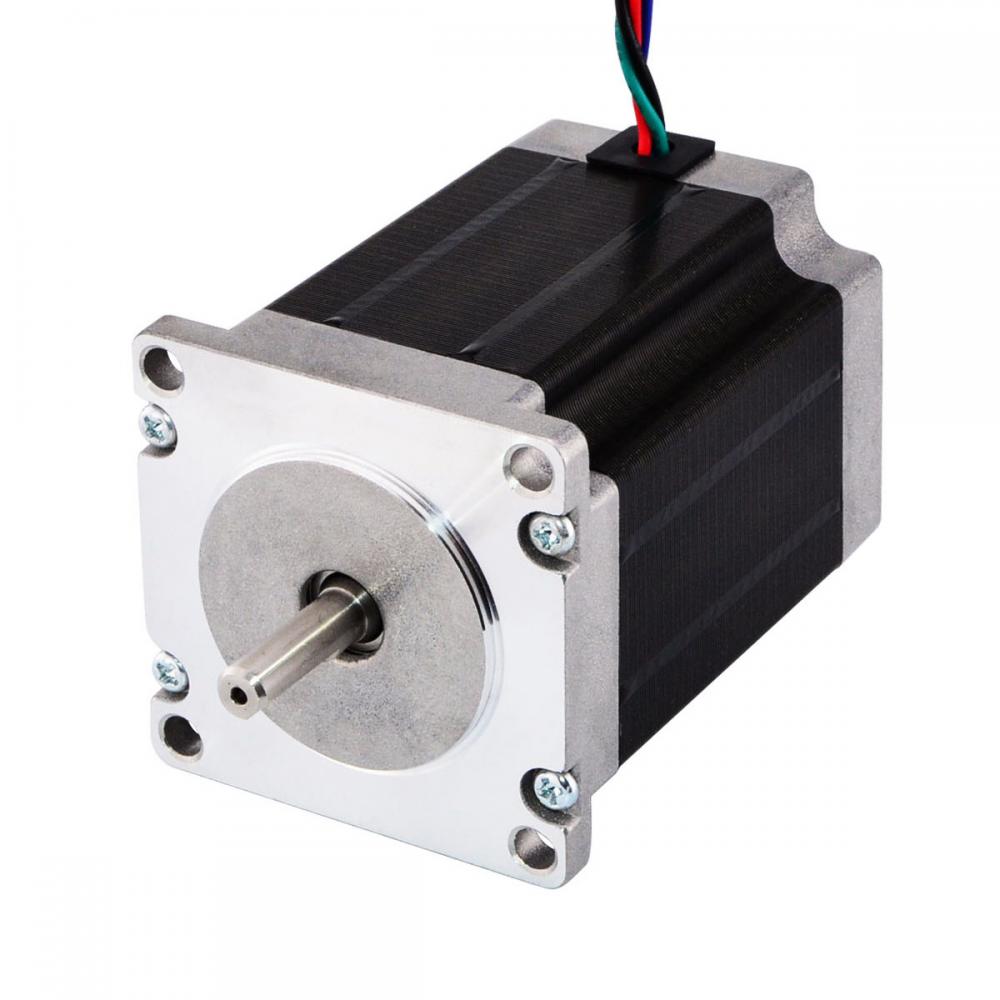

- Nema 17 is for small 2×2 cutting areas

- Nema 23 or for mid-size 4×4 tables

- Nema 34 is for 4×8 tables

- Nema 42 is for 4×8 or bigger

Any of these motors will work on any of the tables above and will move the machine around. But will it cut, if you want to just engrave things a 1/8 deep. You can use Nema 17

The bigger the motor the more torque and the deeper you can cut in 1 pass.

- Nema 23 can cut ¼ inch deep in 1 pass, if you are cutting ¾ inch material it will take 3 passes at ¼ inch.

- Nema 34 and 42 deeper cuts and less passes

Take a hand held router and 3/4 inch material and see how fast you can cut all the way thru in 1 pass. The router can move only so fast as the router bit cuts, a sharp bit works faster then and dull bit.

Why is the router bit dull? Cutting to fast

What stepper motors would I get to be able to do just about anything is a Nema 23/24 and at least 269oz, 2.8 to 3 amps for a 4×4 cutting area and Nema 34 or 42 for 8×10 or larger cutting area.

In reality any motor will move your machine around but you need cutting torque to push the router around when cutting into material without stalling. You can cut anything by setting the right speed for the material you’re trying to cut, just remember there are router bits for wood/Metal/Plastic and for Aluminum, use the right bit…